here’s 1 relays on this controller. Refrigeration and heating mode can be set through the menu. Can be used for domestic freezer, water tanks, refrigerator, industrial chiller, bolier, steamer, industrial equipments and other temperature-controlled systems.

Here is new manual: For STC-1000 temperature controller original scan

For example

- , If you choose Heat mode(Set HC to H). Set Temperature Value to 40°C. Set CP value to 10°C.

- The relay will be connected when the temperature drop to 30°C(set temperature value-CP value). And the relay will be disconnected when the temperature reaches 40°C.

- If you choose Cool mode(Set HC to C). Set Temperature Value to 40°C. Set CP value to 10°C.

- The relay will be connected when the temperature reaches 50°C(set temperature value+CP value). And the relay will be disconnected when the temperature drops to 40°C.

Size:

- Front panel size: 75(L) x 34.5(W)(mm)

- Mounting size:71(L) x 29(mm)

- Product size:75(L) x 34.5(W) x 85(D)(mm)

- Sensor Cable length: 1m (include the probe)

Specifications:

- Measure range: -20°C ~ +100°C

- Slew range of temperature: 1°C-30°C

- Resolution: 0.1°C

- Accuracy: ±1°C (-20°C~70°C)

- Power supply: 220V AC, 50/60Hz

- Power consumption: less than 3W

- Relay contact capacity: Cool(10A/240VAC);Heat(10A/240VAC)

- Data retention: Yes

- Compressor Delay protection: YES

Item Include:

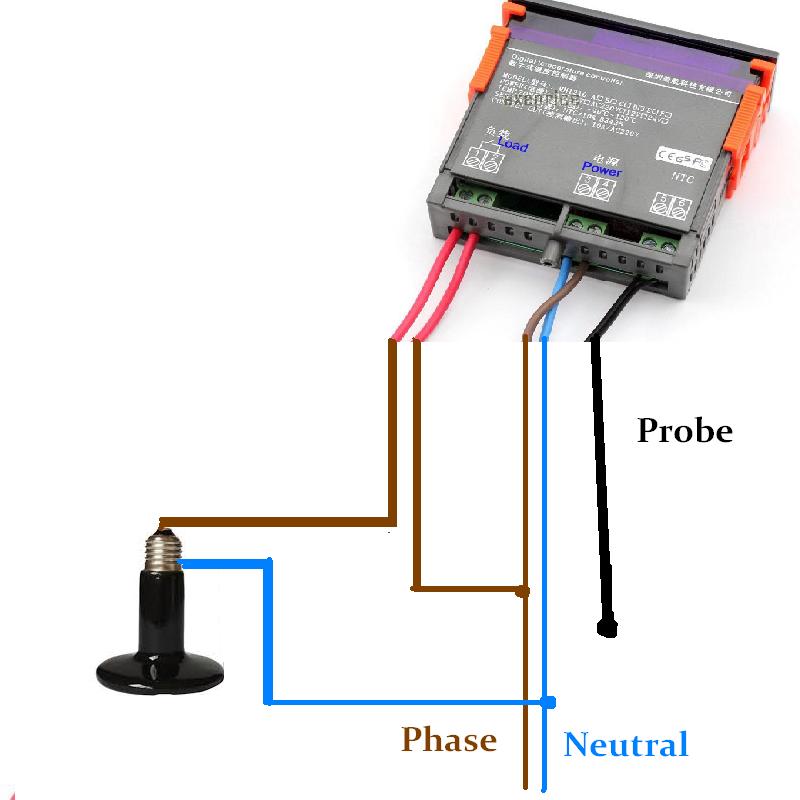

Schematic for cooler/ heater with stc 1000 thermostat

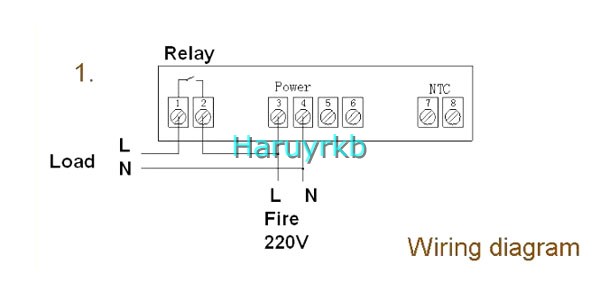

A right diagram of the thermostat stc1000

How a load in a thermostat, we can plug , heater spiral , motor, heater bulb (similar is on picture)

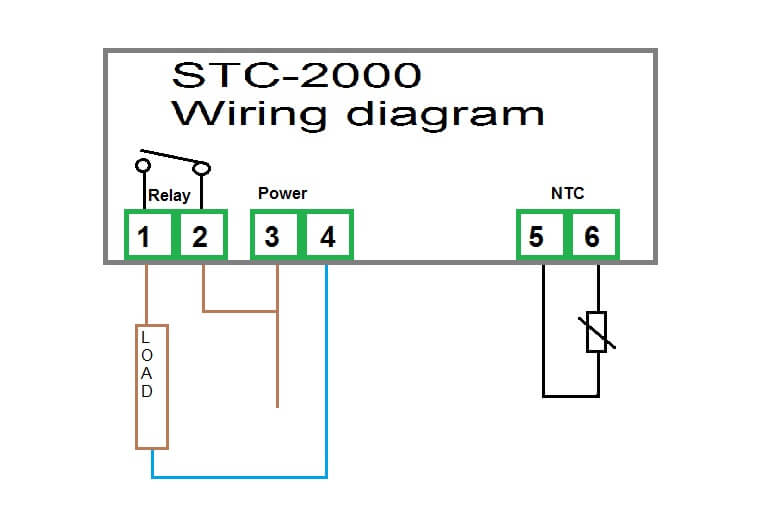

Terminals 1 and 2: Normally opened contact of relay

Terminals 3 and 4: Connect the power 220V

Terminals 5 and 6: The factory parameter settings of thermostat can be locked after a short circuit, the user can not modify.

Terminals 7 and 8: Temperature connection sensor

Note: The load refers to the heating or cooling equipment on control.

③ Electrical performance:

Temperature measurement range: -50 ℃ ~ 110 ℃

Temperature control range: -50 ℃ ~ 110 ℃

Temperature measurement error: ± 0.5 ℃

Sensor Type: NTC (10K/3435)

Control accuracy: 1 ℃

Working current: <2W

Relay contact point current: AC 7A/220V

Data storage : Yes

Working temperature: 0 ℃ ~ 50 ℃

Storage temperature: -10 ℃ ~ 60 ℃

④ Key Instructions:

1. RST: Press RST key to switch on and off, press the RST key on the power-off state once to turn on, on the power-on state, press the RST key for three seconds and hold on, then it will be off.

2. SET:

A: Press the SET key once to enter the temperature control setting, press ▲ or ▼ button to adjust, press ▲ or ▼ button for three seconds and hold to enter the fast adjusting mode, press the SET key again to exit setting mode.

B: Press and hold SET key for three seconds to enter the system menu settings, press the ▲ or ▼ key to select the adjustment menu, press SET key once to enter the appropriate parameter settings, press ▲ or ▼ to adjust the parameters needed to be modified, after being adjusted, press the RST key to exit, or exit as the system delay for 5 seconds.

▲: Up key

▼: Down key

⑤ Operating Instructions:

LED Status Description:

The WORK lights at the left side of the screen is used as working indicator lights, flashing is to indicate the delay of cooling or heating, if the LED is always on ,it indicates it is on the status of cooling or heating .

The SET light at the left side of the screen lights is used as setting indicator lights, if the LED is always on ,it indicates it is on the status of setting.

.

Function Instructions:

Press RST key to open the thermostat, on the running status, press this key for 3 seconds, then the thermostat can be turned off.

◆Cooling, heating function:

Cooling Mode: When the measured temperature is higher than or equal to the set value + hysteresis, the relay picks up to start the output; When the measured temperature below the set value, the relay off and close the output.

Heating mode: When the measured temperature is higher than or equal to the set value, the relay off, turn off the output; When the measured temperature below the set value – hysteresis, the relay picks up to start the output.

Example for Setting: If it is set to heating mode, set the temperature to 25 degrees, hysteresis is set to 5, then when the measured temperature is higher than or equal to 25 degrees, the relay is off, close the output. When the temperature is below 20 degrees, pick up the relay again, to start the output.

Example for Setting: If it is set to cooling mode, set the temperature to 25 degrees, hysteresis is set to 5, then when the measured temperature is below 25 degrees, the relay is off, close the output. When the temperature is higher than or equal to 30 degrees, pick up the relay again, to start the output.

◆ Cooling, heating mode setting:

Press “SET” key and hold more than 3 seconds to enter the menu display, the screen appears “HC” code, press the “SET” key to display the working mode, press the “▲” or “▼” to adjust the display, C means cooling mode; H means heating mode.

◆ Hysteresis function:

Hysteresis setting limits the maximum interval between the opening and stopping, this machine minimum interval between the opening and stopping is 1 ℃, the maximum is 15 ℃.

◆ Hysteresis settings:

Press “SET” key and hold more than 3 seconds to enter the menu display, with “▲” or “▼” key adjusted to the screen, appearing “D” code, press the “SET” key to display the hysteresis set value, press “▲ “Or”▼”key to adjust the parameters.

◆ Temperature calibration funtion:

When there is deviation between the measuring temperature and standard temperature, use the temperature calibration function, make the machine measurements value consistent with the standard temperature, the after calibration temperature= the before calibration temperature + calibration value (calibration value can be positive number, negative number, and 0) .

◆ Temperature calibration settings:

Press “SET” key and hold more than 3 seconds to enter the menu display, with “▲” or “▼” key adjusted to the screen, appearing “CA” code, press the “SET” key to display the temperature calibration settings, press “▲ “Or”▼”key to adjust the parameters.

For example: When we measure the probe temperature was 25 degrees,it displays 25 degrees as the CA is 0, it displays 26 degrees as the CA is 1, it displays 24 degrees as the CA is -1. This function is generally applied when the probe can not measure directly the measured object. For example, we place the probe at the outside of a cup to measure its water temperature, we need to adjust the CA parameters because of the heat loss of the cup, so that the display temperature can be in accordance with cup temperature.

◆ Delay Protection Funtion:

In the cooling mode, the first power on, when the measured value above the set value + hysteresis value, the machine will not immediately start cooling, it needs to set the delay time, then the machine can run to start cooling; once the interval between two cooling is larger than the delay time, the machine immediately starts cooling, once the interval between two cooling is less than the delay time, the machine must run the remaining delay time to start cooling. The delay time is started to calculate from stopping the machine. The delay time of heating mode is as same as the cooling mode.

Note: It is recommended that only the device that use compressor cooling can use the delay start function, the user who don’t need delay start function please set this parameter to 0.

◆ Delay Protection Setting:

Press “SET” key and hold more than 3 seconds to enter the menu display, with “▲” or “▼” key adjusted to the screen, appearing “PT” code, press the “SET” key to display the delay setting value, then press the “▲ “or “▼”key to adjust the parameters.

◆ Upper and lower limit functions:

The setting of HS and LS limit the set range of control temperature point , for example: HS is set to +15, LS is set to -10, the control temperature can only be adjusted between -10 and +15, when the control temperature to -10 then press “▼” key, the display will remain on the status of -10 and not decrease; when the control temperature to +15 then press “▲” key, the display will on the status of 15 and not incease. If the set point outside this range, it needs to firstly change the value of HS and LS, then it can be achieved.

◆Upper and lower limit settings:

Press “SET” key and hold more than 3 seconds to enter the menu display, with “▲” or “▼” key adjusted to the screen, appearing “HS” or “LS” code, press the “SET” key to display the upper or lower limit set value, Then press “▲” or “▼” key to adjust the parameters. HS means upper limit. LS means lower limit.

For example: the upper and lower limits are used to limit the range of control temperature that can be set, such as: LS is 10, HS 20, then press the SET key to adjust the temperature control, it can only be varied between 10 and 20.

◆ Menu code selection:

|

Symbol |

Details |

Setting range |

Factory settings |

Units |

|

HC |

Heating / cooling |

H/C |

C |

|

|

D |

Hysteresis |

1~15 |

5 |

℃ |

|

LS |

The minimum set limit |

-50~110 |

-50 |

℃ |

|

HS |

The maximum set limit |

-50~110 |

110 |

℃ |

|

CA |

Temperature calibration |

-5~+5 |

0 |

℃ |

|

PT |

Delay time |

0~10 |

1 |

Minutes |

⑥ fault tips:

1)When the sensor disconnected, the screen displays — and close the heating wire

2)When the sensor detects the temperature is below -50 degrees, the screen displays LLL

3)When the sensor detects a temperature higher than 110 degrees, the screen displays HHH

⑦ Caution for using:

◆ Cooling, heating load must not exceed the output contact capacity, or it may result in machine damage and cause a fire.

◆ Various connecting wire must be well connected with the terminal, otherwise, it would result in reducing the reliability of machine.

◆ When connecting the wire, please separate power supply, relays, sensors, otherwise it will damage the machine.

I can’t believe I haven’t seen this website before! Overall, this tutorial/instruction guide was awesome! Turns out my wiring was off a touch, forgot to splice the neutral lead…or whatever. Bottom line, I didn’t burn my house down and I learned how to wire it properly! Also, the instructions that came with my device were in broken english, at best. This gave me the answer to all the questions I had. I can’t wait for garage sale season…I’m gonna grab all types of weird crap.

I ordered two of the atc1000s and plan on using them to start the circulaters on my sloar colectores. Just confused on the high low limit range. I would like to set it up to start at 170 and shut off at 140. does it have that much range?

Steve Howard,

if you did not find out by now, the specs for this controller shows the range to be between -50 to +110degrees Celsius. Unless you are talking 140 -170 Fahrenheit you can not use it. If you are talking Celsius, the controller would show EEE as in ‘error; out of range, and the probe lead would more then likely get damaged because of excessive heat.

If however, your range is in Fahrenheit degrees, you can. -50 C is -58F and 110 C is 230F.

Hi really good to get this info but Im confused as to why the picture with coloured wires appears to be in reverse to the wiring diagram neutral appears in revers positions

It matters not. The picture shows mains operated model. It has a small transformer built in to provide the power to the unit, so it makes no difference, neutral and phase can be transposed. having said that, one should always feed/switch, the phase lead through the relay, for safety.

If a model is DC powered, 12V or 24V, polarity MUST be observed

Hi I should add to my comment.

I am using a 12 volt version on my isotherm boat fridge

Did you manage to come right? I have tried several times. Do you know is it possible to use the existing temp probe?

Is it possible to set this controller at constant 100°f?

Yes but recommend hysterezy 1C

Hi

I have a 240v 1-pahse electric motor running a chiller compressor (Sanden with 12v magnetic clutch). I want my Temperature Controller to start the motor on top temp range, then disengage the compressor clutch with a start delay.

At bottom temp range I want to do the opposite… engage the magnetic clutch (stop the compressor), then stop the electric motor with a stop delay.

Is this possible with the STC-1000?

Thanks and regards