In my review I will describe my 2 year experience with the STC-1000 temperature cotroller. In this article, you can read the pros and cons of the product, manual and wirring guide how to set it up and where to buy it.

Its bigger post please use navigation menu for quick move:

Navigation index:

- Price and buy

- My review pros and cons

- Instruction Guide Manual STC-1000

- Moding temperature controller

- Complete technical parameters

Price and buy

My favorite seller is the Chinese seller KETOTEK, his thermostats are solidly packaged and have always worked correctly for me so far. The versions you can buy are 12V/24V and AC110-230V (voltage range 90-250V) when buying, please note the difference between Fahrenheit and Celsius.

Package includes :

1 x 220V or 110V Mini Digital Temperature Controller STC-1000

1x temperature probe NTC10K

1 x Instruction Manual

My review:

Now I am describing my experience with the STC-1000, I tested about 12 pieces work very well. Read the pros and cons of this product:

- Have 2x relay one for heating , one for cooling

- Good to maintain a precise temperature, prevent overheating or excessive cooling

- You can set the temperature exactly, you can increase or decrease after 0.1C steps

- Small size and have clips in the panel

- Price is very good – 8-15usd

Here is cons:

- A bit more difficult to set up than temperature controller MH1210W

Review conclusion:

It is a good device with a good price.You pay from 8-15 usd (even with shipping) and you will get a stable device that you can set to high accuracy.

The disadvantage is The disadvantage is the harder control – For example, if you want to set the temperature you must hold the SET button with one thumb and press the arrow keys with the other hand more in manual guide (scroll down).

My rating is positive before writing reviews I tried about 12 pieces of STC 1000 .

The best use this STC-1000 temperature controller is in the hatcheries ,incubator,animal care sensitive to the correct temperature like in aquarium. It is good in boilers for heating water or in refrigerators and freezers, DIY projects,has been used in many keezers, kegerators and fermenters.

Here is other versions of STC-1000

-

DTC1201 (different design but practically STC-1000 with wifi tuya app)

Detailed description of temperature controller STC 1000

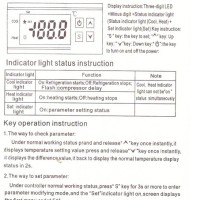

Now I will describe thermostat and control , i will try to describe accurately.The device STC 1000 includes five main components:

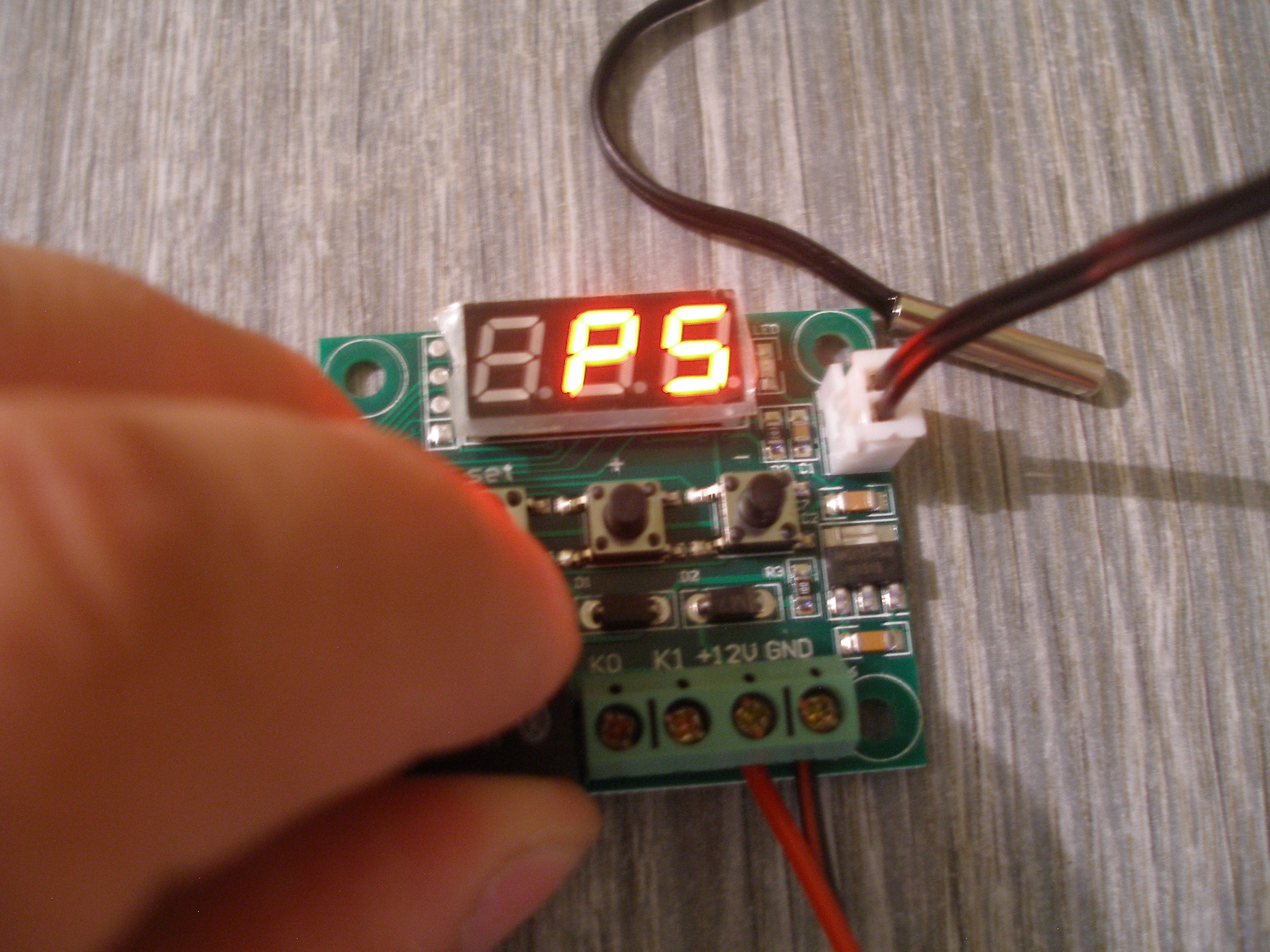

- The display is red, it shows three digits four.clearly shows the temperature value withe the one decimal place.

- Below the display are four buttons which control the thermostat STC 1000. First buton is button is on / off Below it is“SET” button with next two arrows buttons are + and – are used for menu navigation increasing or decreasing values.

- The display has diodes one shows that the thermostat has activated witch relay is ON (cooling or heating). The the third diode lights up when you set the thermostat, called SET.

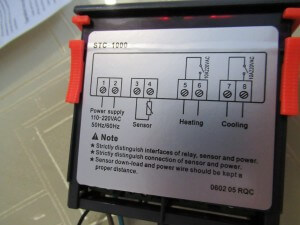

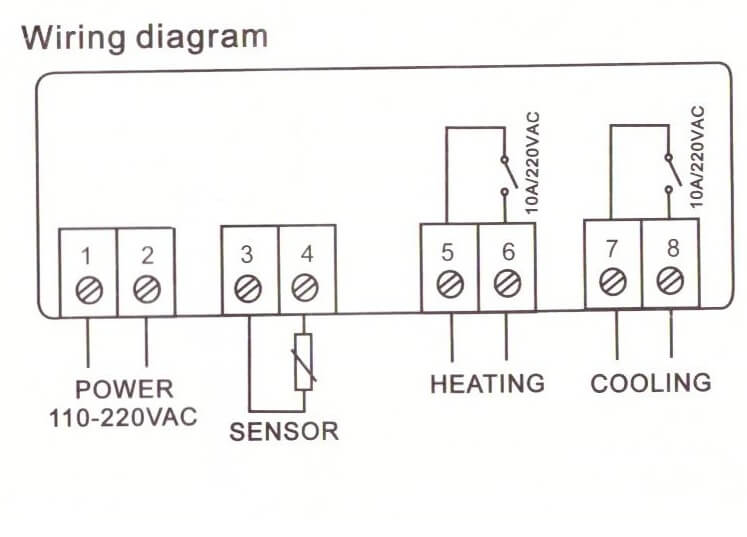

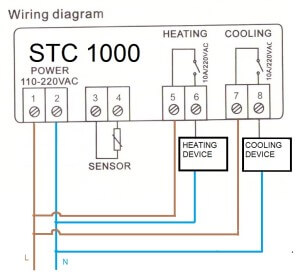

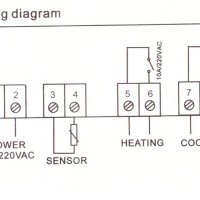

- Do we involve green terminal two terminals 1-2 is for power AC 110/220V (230V) , terminal 3-4 for temperature sensor, terminals 5-6 is for heating relay 7-8 for cooling relay .

- The sensor for the temperature controller STC is placed in 3-4 terminals. It is about 80 cm long with active iron end.Type of temperature sensor is classic NTC 10K

Note: STC1000 can buy in multiple variations the most common versions of the temperature controller are:

- Only 220V (for European market).

- 220/110V Universal for US and European market.

- Temperature showing only in Fahrenheit grades.

- Temperature showing only in Celsius grades.

When purchasing carefully, select the right model

STC-1000 temperature cotroller wirring and manual how to setup.

In this manual, I will show you how to properly connect and set up a good temperature controller STC1000.

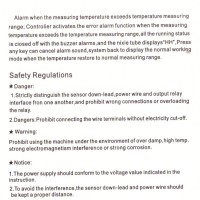

How to properly connect terminals ((Do not connect under electric current))

Please read this verified manual carefully.

Here is wiring diagram:

Here is alternative schematic with with electrical wires:

Note:The temperature controller can work with booth device heating and cooling, or with one from this.

Now if you have Now that the wires are properly wired (in 1 and 2 terminal) controller automaticaly start- complete here is setup manual:

STC 1000 manual guide:

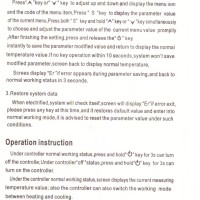

Here is complete easy manual for STC 1000 temperature controller now i describe buttons:

SET button use to set the thermostat, if you Holds for 2 seconds and the thermostat displays the menu with functions F1,F2,F3,F4, (I will explain in detail below)

Arrows is for to increase and lower values

On -Off button is for activation and deactivation

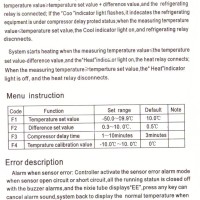

Long pusch button SET and going in STC 1000 menu F1,F2,F3,F4:

F1: SET GOAL temperature : pusch SET button again and here see currently set temperature , If you want to change it, press SET again with the up or down arrow (whether or not you want to increase or decrease the temperature). Remember SET + arrow

F2: Hysteresis od sleewe range : in manual called “Difference set value ” is gap when booth relay turn off…For example, if you set 1 degree

When the temperature is raised to a target temperature of, for example, 30 degrees of the relay for heating, it is switched off , If the temperature rises further and exceeds 31 degrees, the cooling relay switches on.

F3:Compressor delay time: time for wait after reach goal temperature , if you set 3 min temperature controller wait 3 min , after 3 min turn on relay.

F4:Temperature calibration: You can make the Stc-1000 very accurate, just compare the temperatures with a verified thermometer (best compare at the target temperature) you can increase or decrease the temperature after 0.1C steps.

This is explained in detail in the original manual here is complete scan:

MOD and firmware upgrade :

Maybe it’s for technical enthusiasts but there are some interesting ideas on the Internet that modify the controller STC 1000.

These interesting features can be added:

- Vanilla Plain version, with no extra features.

- Dual Probe Use a second temperature probe to put limits on ambient temperature.

- Fine Offset 433MHz Send temperature data wireless (emulate wireless thermometer).

- Communication -Use an arduino to send/receive data to/from the STC.

Mod STC 1000 with aurdino https://github.com/matsstaff/stc1000p

Dual probe : https://club.coopers.com.au/coopers-forum/topic/14688/

Firmware upgrade:http://hackaday.com/2014/03/15/temperature-controller-gets-open-source-firmware-upgrade/

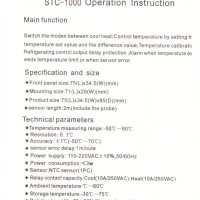

STC 1000 Technical data:

- Temperature measuring range : -50 – 99°C;

- Resolution : 0.1°C;

- Accuracy : ±1°C (-50 – 70°C);

- Sensor error delay : 1 minute

- Power supply : 220VAC±10%, 50/60Hz;

- Power consumption : ≤3W;

- Sensor : NTC sensor (1PC);

- Relay contact capacity : Cool 10A/250VAC;Heat 10A/250VAC;

- mbient temperature : 0 – 60°C;

- Storage temperature : -30 – 75°C;

- Relative humidity : 20% – 85% (No condensate).

Specification and size :

- Front panel size : 75(L) x 34.5(W)(mm)

- Mounting size : 71(L) x 29(W)mm;

- sensor length : 1m (include the probe).

- Product size75(L) x 34.5(W) x 85(D)mm;

Package includes :

1 x 220V or 110V Mini Digital Temperature Controller Thermostat

1 x Instruction Manual

hi

i need some advice please i bought a second hand marine set up fitted with a stc 1000 it was working when i picked the tank up it was left off for about 8 hrs when i turned it back on an alarm went off and its showig EE can someone please tell me how i can get it back to where it was .

thanks tim owen

check your sensor it might be not tightly attached

I am an OEM of a automatic horse waterer. The unit holds 1 gallon of water. I need to keep this from freezing therefore I am in need of a controller. I have a 300 watt Immersion heater installed and I also have a 1/2″ Female NPT coupling installed for a temperature sensor/ thermowell. I am thinking that I would like to use the STC-1000. I am checking to find out if I can use a temp. sensor that would go inside say a thermowell and then wire into the controller. Can you help me? I need some advice. Thank you very much.

I can how many meter length cable increase for sensor

i have experiences with 5 meters is ok , maybe more temperature controller can be calibrated

Bonjour

je viens d’acheté un STC 3008 pour géré la température du caisson de mes imprimante 3D ,je voudrais savoir comment faire pour branche des ventilateur au contrôleur de température afin que ce soit lui qui d’éclanché les ventilo des que la température est trop haut .

pouvez vous m’aide s’il vous plait dans cette démarche car je ne sais pas si je doit tous connecté a une arduino ou pas au niveau de l’alimentation électrique je les branche sur l’alimentation de l’imprimante mes pour le reste je ne sais pas comment faire

en vous remerciant pour votre aide cordialement

Philippe

hello…im trying to wire a 12v diaphram pump to my stc 1000 dc temperature controller so the pump will shut off at -1C and turn on at +2C…any thoughts or ideas would be greatly appreciated…im in the dark…thanks for your time

Hi ..you must set goal temperature F1 -1C and F2 +3C use relay for cooling

You did a great job with detailing this product you were very thorough lots of good information